WATER TREATMENT EQUIPMENT

The quality of source water shall meet the requirements of GB5749-2006 Sanitary Standard for Domestic Drinking Water. If there are special pollutants in the source water, users need to inform them in advance so that our company can do special treatment.

Technical Parameters

|

|

| ||

|---|---|---|---|

|

|

Work pressure | 0.8 | Public Administrate |

|

|

Water supply pressure | e0.25 | Public Administrate |

|

|

Water supply flow |

e1.0/2.0/3.0 | Cube |

| Outlet flow | 250/500/1000 | LIH | |

| Operating temperatures | 5-45 | C | |

| Electrical parameters | 220 | V | |

| Hertz | 50 | Hz | |

| Power | 1100/1500/1800 | W |

Functional Overview

The tap water has undergone three stages of pretreatment: PPF filtration, carbon filter and precision filter, and then enters the reverse osmosis system after being supercharged by the high-pressure pump. The quality of effluent meets the national sanitary standard for barrel drinking water.

- PPF filter mainly removes granular impurities, fibers, suspended objects, colloids and other substances in the water to reduce oil level. Under normal working conditions, the effluent SDI<

- 5.0, turbidity < 1.5NTU

- Carbon filter mainly removes organic matter, odors and other organic matter, odors, etc.

- Color and carcinogen triges methane, etc. Under normal working conditions, free chlorine<.

- 0.1PPM to prevent its oxidation reverse osmosis membrane.

- The function of the filter is to prevent accidental particles such as activated carbon and resin from entering the reverse osmosis system, causing mechanical damage to the membrane.

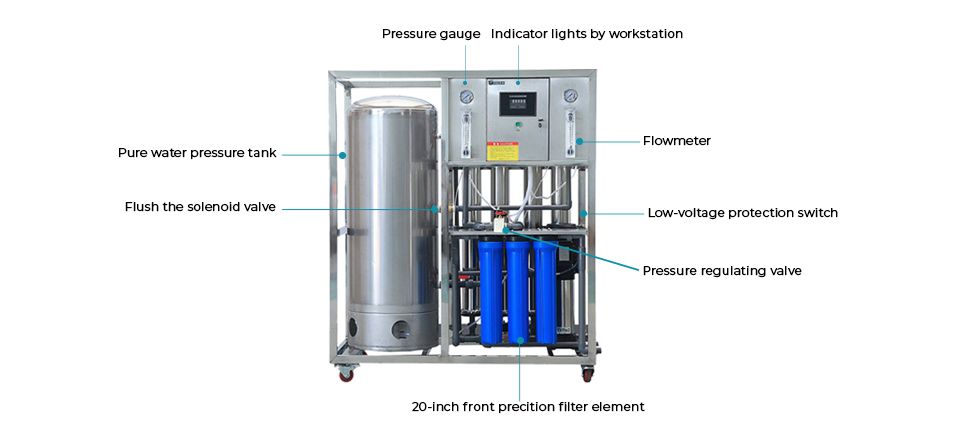

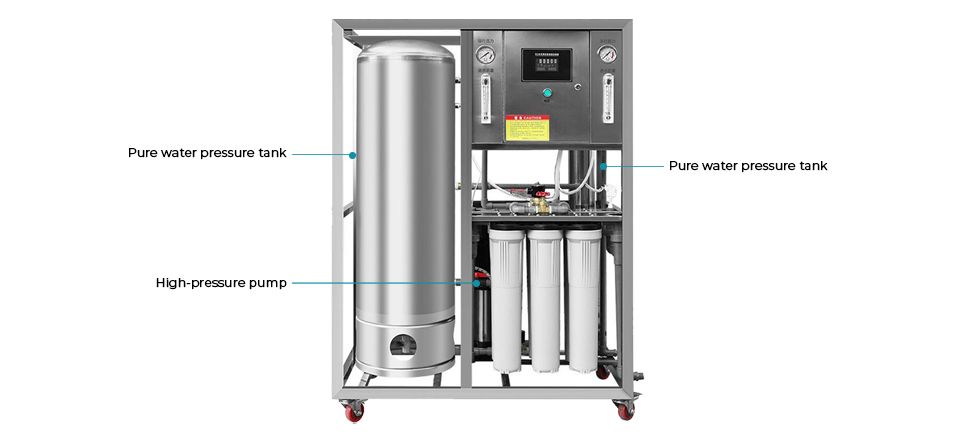

- The reverse osmosis system consists od stainless steel high-pressure pump, stainless steel membrane shell, reverse osmosis composite membrane, electronic control unit, concentrated fresh water proportion, flush solenoid valve, flowmeter, pressure gauge, rack, etc. The principle is to use the principle of reverse osmosis of the water molecules in the raw water driven by a high-pressure pump. The reverse osmosis membrane intercepts organic salts, heavy metals, electrolytes, chemical pollutants, bacteria, viruses, heat sources, etc. In the water and drain them in the concentrated water phase and discharges them with, the concentrated water, and pure water molecules and oxygen molecules pass through the reverse osmosis membrane. Form deionized water purification.

Installation

- 5.1 Connect the inlet (DN20/25 outer wire), outlet (DN15/20 outer wire) and drainage outlet (DN15/20 outer wire) according to the label on the machine

- Water inlet valves need to be installed, and no water outlets and drain can be installed

- Doors to avoid irreversible damage to the machine

- 5.2 The effluent of the machine cannot be directly connected to the pipe. Buffer devices, such as water tank or pressure tanks, must be installed. If the equipment itself has a pressure water storage tank, you can ignore.

Startup Operation

- 6.1 Open all inlet valves. The pressure gauge to be raised to

- 0.25Mpa up, turn on the power switch, and turn on the reverse osmosis after the high-pressure pump starts.

- Installation and. After 10-20 seconds, set up an uncontrolled water fast light. At this time, adjust the thick water-free ratio on Shiyue to the net, so that the flow ratio of concentrated water to water purification is 2:1. If there is no water delivery at this time, please turn off the equipment immediately and #connect the after-sales service staff, and the fragrance will cause irreversible damage to the reverse osmosis membrane.

- c6.2 in the early stage of the start-up of the machine, the panel flushing lights up, and at this time,the flush electromagnetic pity.

- Open it and flush the reverse osmosis film with high flow. After 20 seconds, the machine will be automatically installed to a normal water production state. If the flushing lamp and the water shortage lamp flash alternately at startup, please refer to Article 3 of Item 6 below.

Fault Detection

If the reverse osmosis device cannot be started or stop running within 10 seconds of startup, fault detection should be carried out.

| Serial Number | Breakdown | Reason | Exclusion Method | |

| 1 | The power supply is turned on, but the RO host is not working | The wire fell off the inlet was not opened | 1. Connect the wires 2. Open the water | |

| 2 | The pump runs, but it doesn't reach Rated pressure and flow | The security filter element is too dirty there is air in the pump | 1. Clean or replace the filter element 2. Remove air from the pump | |

| 3 | After turning on the switch and entering the water pumps start and stop frequently | Water inlet pressure or flow is too low | Increase the water pressure or flow | |

| 4 | Poor water quality | Membrane contamination scaling membrane perforation | According to technical requirements chemical cleaning and replacement of new film | |

| 5 | Decrease in pure water production | Membrane contamination scaling changes in water temperature | According to technical requirements chemical cleaning and replacement of new film |

Operation of Shutdown and Deactivation

When the reverse osmosis device stop working, it must be turned on for at least 5-10 minutes for 3 days to prevent bacteria from growing in the membrane. When the machine stop for a week or more, a 1% food-grade sodium bisulfite solution diffuse membrane should be added.

- When the reverse osmosis machine is back in operation, the disinfectant must be washed off.

Maintenance

- 9.1 Every time the water main engine is started, the electromagnetic que will automatically flush the film, and the rinse is 18 seconds.

- c9.2 Replace PPF and activated carbon filter elements

The host is equipped with a pre-filter and a 20-inch front filter element, which can effectively block accidental particles of the pretreatment system from entering the reverse osmosis membrane. When the water inlet pressure drops

At 15%, it may be because the PPF filter element is blocked and should be replaced in time. When replacing, unspin the security filter plastic case, remove the contaminated filter element, replace it with a new filter element, and then tighten the security filter plastic case. Be careful not to damage or lose the rubber seal ring in the filter case when replacing. See the picture below

At 15%, it may be because the PPF filter element is blocked and should be replaced in time. When replacing, unspin the security filter plastic case, remove the contaminated filter element, replace it with a new filter element, and then tighten the security filter plastic case. Be careful not to damage or lose the rubber seal ring in the filter case when replacing. See the picture below

Wiring Instruction

The power supply inlet is connected to the top inlet port of the leakage circuit breaker in the box, which requires a copper core wire of more than 1.5 square meters. The full water control cable is connected to the terminal of the full water switch on the wiring row (removing the original short wiring).